About Us

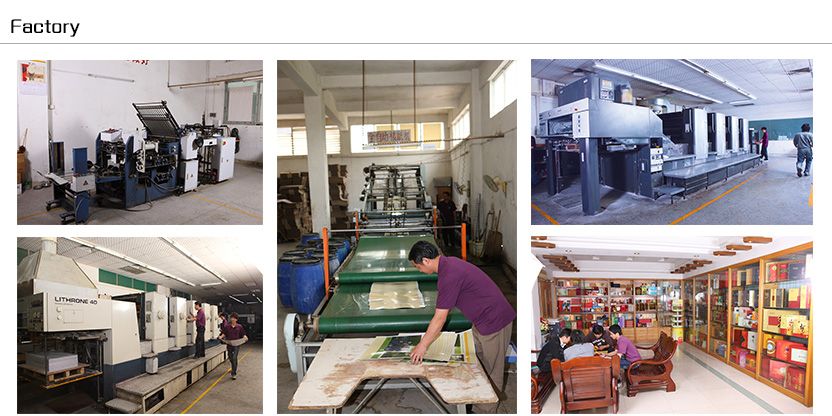

Swift Packaging Solutions is committed to providing one-stop service on clothing underwear packaging procurement.

We have a full experience of cost control and quality control in the clothing packaging, underwear packaging industry. With 5 factories covering almost any kind of packaging available we are ready to take on both design and production tasks for a wide range of customers.

We make an honor of treating all projects, big or small, with the same level of enthusiasm and hope to hear from you! Please dont hesitate to get in touch for a quotation or a free sample - no strings attached!

We would like to make donation activities in the name of the our clients in order to express them our appprecication for the good copperation and the good relationship with us, also we hope our donation activities can help the UNICEF children to have better life.

-

Amy Lei

Amy Lei

+86 13928843163

-

Joyce Yan

Joyce Yan

+86 13928843163

-

John Lamboard

John Lamboard

+86 13928843163